Research Areas

Korea Textile Machinery Convergence Research Institute

Future Component and Equipment Research

Core Technologies

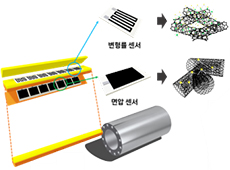

Sensor-Embedded Smart Roll Design Technology

This technology, widely applicable to secondary batteries and textile machinery, embeds composite-based pressure sensors into pressurized and heated rolls, enabling real-time pressure measurement.

Its core lies in optimal internal roll design and the design/manufacturing of composite-based sensor cartridges, allowing consistent product quality through real-time pressure sensing and feedback control.

phone_in_talk Technical ContactAX Component & Equipment Research Department

Advanced High-Tech Roll Technologies for Next-Generation Product Manufacturing

- Surface treatment technology for developing high-durability rolls.

- Design and analysis technology for high-precision, high-load rolling rolls.

- Induction heating-based temperature control technology.

- Reliability evaluation technology for rolls and roll-to-roll systems.

phone_in_talk Technical ContactFlexible Manufacturing System Research Department

AI-Based Autonomous Manufacturing Technology for Multi-Product Flexible Production

- Edge-controller-based process data acquisition and equipment control technology

- Preprocessing and data compression technology for manufacturing processes

- Vision-based classification, segmentation, and image recognition AI models

- Recurrent neural network AI models based on time-series data

phone_in_talk Technical ContactFlexible Manufacturing System Research Department

Electric Energy Conversion and Motor Drive Technologies

- (Power Conversion) – DC/DC converter and inverter design technology

- (Motor Drive) – High-performance electric motor control technology

phone_in_talk Technical ContactEnergy DX Research Department

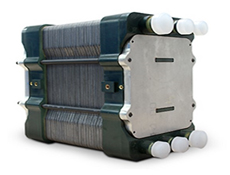

Core Manufacturing Technologies for Hydrogen Fuel Cells

- (Electrode Catalyst) High-dispersion technology for catalyst slurry

- (Electrode Coating) Uniform coating and stabilization of electrode catalyst layers

- (Separator Shaping) Large-area thin-film flow field design and patterning

- (Fuel Cell Control) Hydrogen gas supply and humidity management control

- (Manufacturing Equipment) Large-area MEA manufacturing equipment technology

phone_in_talk Technical ContactEnergy DX Research Department

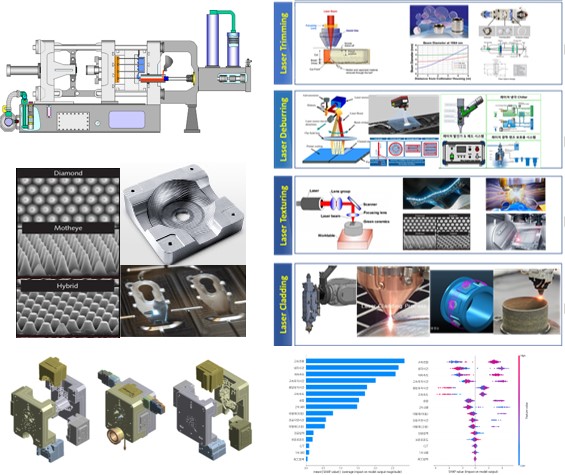

Lightweight Component (Metal, Nonferrous, Composite) Manufacturing and Evaluation Technology

Comprehensive R&D is conducted across the lifecycle of lightweight components made from metals, nonferrous metals, and composites, from process optimization to functionalization and precision evaluation. Technologies such as die casting, casting, forging, plastic forming, and laser machining are employed to achieve both lightweight and high performance. Precise evaluation supports the development of high-performance lightweight components for industries such as future mobility, aerospace, defense, energy, and electronics.

phone_in_talk Technical ContactAX Component & Equipment Research Department

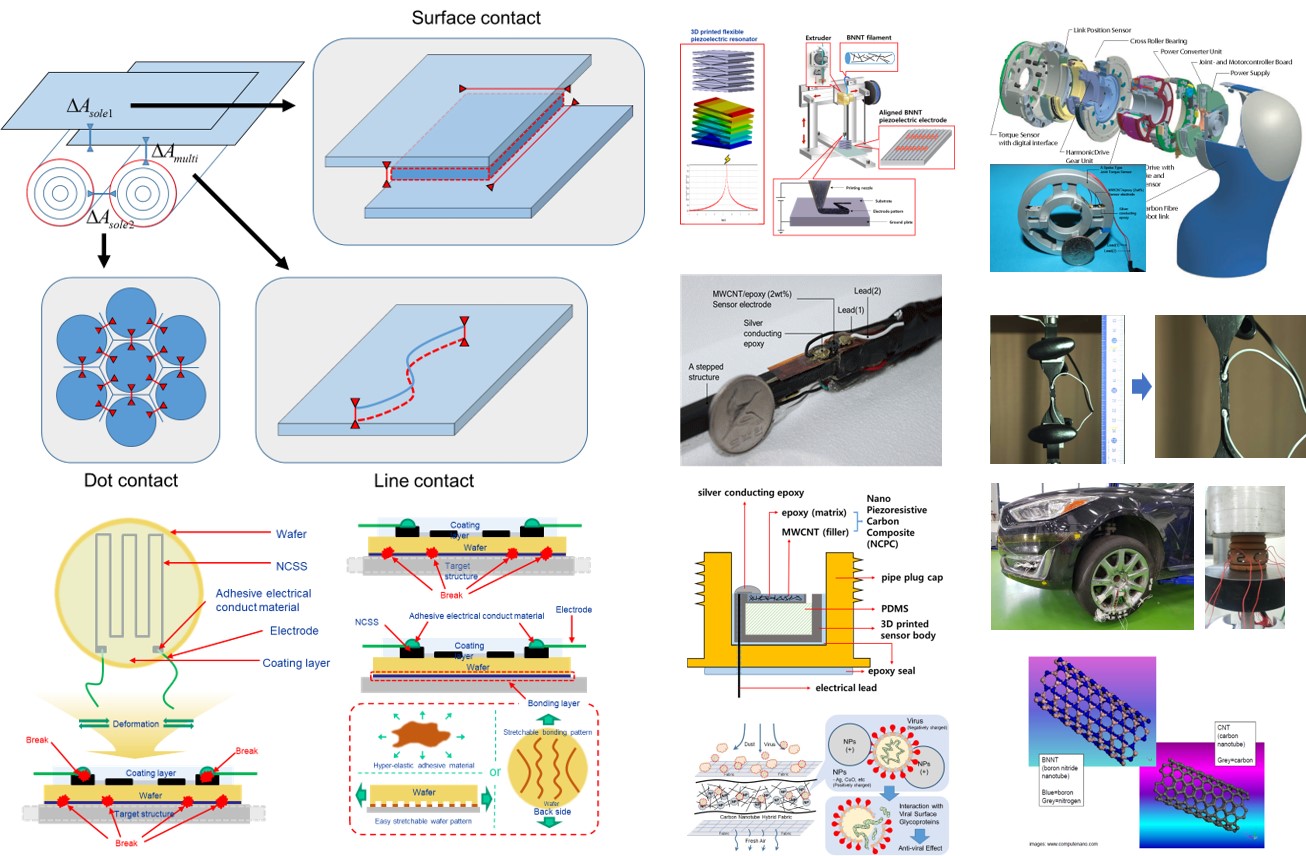

High-Performance Sensor and Flexible Device Technology Based on Nanomaterials

- Design and fabrication technology for intelligent sensors and energy harvesting structures based on nanomaterials like CNT, Graphene, and BNNT.

- Flexible sensor technologies based on high-sensitivity piezoresistive and piezoelectric responses using electrical and mechanical properties (e-skin, wearable devices, etc.)

- Design of artificial neuron-type tactile sensor systems capable of fast response and directional sensing

- Embedded structural sensor and measurement system technology for extreme environments such as high temperature and pressure

- Cost-effective and high-efficiency sensor fabrication processes using solution casting and 3D printing

phone_in_talk Technical ContactAX Component & Equipment Research Department