Department Introduction

Korea Textile Machinery Convergence Research Institute

Research Headquarters

- Discovering major projects and leading technology planning in convergence mechanical industries and material application convergence technologies.

- Establishing mid-to-long term development plans for the headquarters.

- Overall coordination, collaboration, and performance enhancement among research departments.

- Research management of the headquarters.

Head of the Research Headquarters: Park Si-woo

+82-53-819-3137

siwoo@kotmi.re.kr

Energy DX Research Department

The Energy DX Research Department focuses on R&D of core technologies for energy conversion and storage and solutions for energy diagnostics and management due to the growing importance of carbon neutrality. In particular, we are actively promoting R&D for smart manufacturing equipment, lifetime prediction, and integrity enhancement through on-device digital transformation in various industrial machinery sectors including textile machinery. In addition, we are committed to securing future energy technologies, including core equipment for solid-state batteries and productivity improvement of hydrogen fuel cells.

Main Tasks

Carbon-Neutral Energy Technology

- Development of motor design and electric motor control technology.

- Development of BMS evaluation and design technology.

- Development of battery performance evaluation and degradation prediction technology.

- Development of design technology for commercial battery module systems.

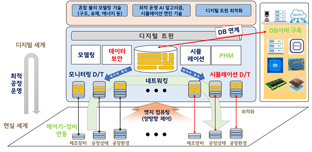

Digital Transformation of Manufacturing Equipment

- Data collection and real-time streaming technology.

- Digital twin technology.

- Embedded edge system design technology.

- Technology for enhancing security and reliability.

- Diagnosis and prediction model technology.

Future Energy Technology

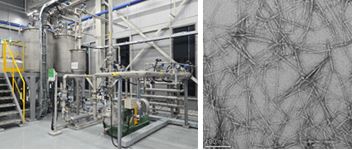

- Development of high-pressure dispersion technology for carbon-based conductive materials.

- Development of ultra-thin primary electrode coating technology.

- Development of deviation prevention technology for cathode material laser notching.

- Development of coating stabilization technology for MEA electrolyte membranes.

- Development of large-area carbon material separator plate shaping technology.

Energy Diagnosis and Management Solutions

- Load monitoring, analysis, and load quality diagnosis technology.

- Modeling and analysis technology for heat and power source equipment.

- Technology for carbon emission prediction and management.

- Comprehensive energy balancing management technology.

AX Component & Equipment Research Department

We aim to advance convergence industries and enhance AI-integrated technologies based on precision equipment and component technologies in the textile machinery sector.

To achieve this, we collect core manufacturing databases and conduct research on AI-based recognition/classification/optimization, sensor-embedded lightweight component design, and core modules for waste resource recycling.

Our department strives to strengthen the competitiveness of equipment and components in future manufacturing industries through continuous technological innovation and collaboration, and to contribute to the commercialization of research outcomes through expanded cooperation with industry and academia.

We aim to establish ourselves as a leading department for innovative equipment and component technologies for a sustainable future, based on the latest research trends and technological developments.

Main Tasks

AI-Based Integrated Technology for Manufacturing Equipment and Components

- Core database collection technology for manufacturing processes.

- AI-based recognition and classification technology.

- AI-based process condition optimization technology.

- Advanced component and equipment design based on manufacturing databases.

Smart Lightweight Component Technology

- Smart functionality technology for lightweight components.

- Forming technology based on lightweight materials.

- AI-based measurement and module technology.

- Research on structural design and process optimization of key components for composite material manufacturing.

Waste Resource Recycling Equipment and Component Technology

- Waste recognition, decision-making, and sorting technology.

- Component and equipment technology for waste treatment and resource recovery.

- Recycling equipment design and simulation technology.

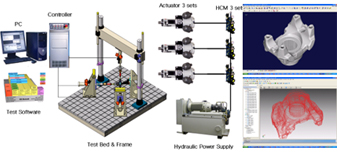

Design, Analysis, Material Testing, and Durability Performance Evaluation

- Reverse engineering and simulation technology for key components and equipment.

- Evaluation and analysis of processing performance (precision, accuracy).

- Optimal design technology through structural and heat transfer simulation.

- Analysis of material testing including basic physical properties, wear, fatigue, and high temperature.

- Durability testing and evaluation of products using single-axis and up to 3-axis combinations.

Flexible Manufacturing System Research Department

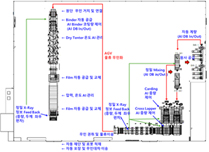

Based on Roll-to-Roll (R2R) manufacturing technology, we develop flexible production systems and autonomous manufacturing technologies, leading the next generation of smart manufacturing innovation.

We utilize AI, IoT, data, and robotics technologies to build optimization and unmanned solutions for industrial processes, while securing multi-physics analysis and reliability evaluation technologies.

Through this, we accelerate the digital transformation of traditional manufacturing, apply research outcomes to industrial sites, and drive innovation in production systems and manufacturing activities.

Main Tasks

R2R Core Component Technology Development

- Core component and R2R process design technology

- Multi-physics dynamic analysis technology

- Performance and reliability evaluation technology

- Digital-based design and evaluation platform technology

AI-Based Autonomous Manufacturing Technology

- Process data collection, analysis, and reinforcement technology

- Industrial AI technology based on time-series and vision data

- Virtual design technology for energy machinery

- Robot technology for autonomous manufacturing

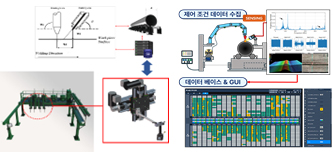

Advanced Robot Convergence Research Department

The Advanced Robot Convergence Research Department develops technologies necessary for building unmanned factories by researching articulated robots, mobile robots, AI, vision, and smart grippers included in advanced robotics.

By expanding robot automation technologies developed and validated in textile factories to the automotive, food-tech, and agriculture industries, we aim to promote robotization in both manufacturing and service sectors, contributing to market growth for robotics companies and enhancing the competitiveness of core industries including textiles.

Main Tasks

Advanced Robotics Convergence Field

- Development of precise control technology for tools and manipulators for high-difficulty tasks

- Development of mobile manipulation technology

- Development of autonomous work planning based on workspace and task-state recognition

- Development of multi-robot swarm control technology

AI Advancement Field

- Development of vision inspection technology through object area recognition and segmentation

- Development of anomaly detection technology through sensor fusion

- Development of process optimization algorithms utilizing AI in the textile industry

Autonomous Manufacturing Field

- Development of automation technology for manufacturing equipment and components

- Development of data communication and acquisition technology between heterogeneous equipment

- Development of advanced robot utilization technology in manufacturing processes

- Development of process-specific AI models and control technologies

XR Digital Transformation Field

- Development of augmented reality work guide technology applying XR+DNA technologies in manufacturing

- Development of technology for digital extraction/learning/reproduction of expert know-how in the manufacturing field

- Research on the application and utilization of metaverse technology across manufacturing industry streams

Composite Materials Research Department

We research core technologies by integrating composite material technologies with diverse product manufacturing processes and focus on developing and supporting composite-related technologies to enhance the technical competitiveness and advanced production systems of SMEs and mid-sized companies.

Main Tasks

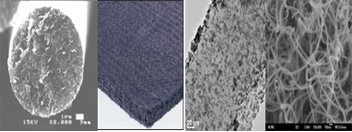

Functional Carbon Materials

- Development of low-cost carbon fiber

- Development of activated carbon fiber materials and filters

- Development of lithium battery anode materials and fuel cell catalysts

- Development and application of nano carbon materials

Textile Machinery Field

- Development of recycling-based resource re-utilization technologies

- R&D on special industrial fibers (defense, firefighting, police)

- Development of manufacturing process control for reinforcement yarn (RFY) systems

- Development of industrial textile machines through 3T (Temp., Tension, Time) optimal design

Polymer Composite Forming Equipment and Evaluation

- Development and consulting for polymer composite forming and processing equipment

- Development of highly reliable electromagnetic shielding polymer composites

- Development of composite molding technology for personal protective equipment (PPE)

- Development of interfacial bonding enhancement technologies between fiber and matrix

- Evaluation of physical, mechanical, and thermal properties of fiber and polymer composites

System Analysis and Performance Evaluation

- Structural and forming analysis of composite materials and manufacturing equipment

- Analysis and performance evaluation of lightweight materials and equipment

- PCM molding analysis based on CFRP lamination patterns

- Process design of AFP (Automated Fiber Placement) head

Green Materials Research Department

We research the convergence of green bio and nanofiber material technologies required in industrial sites and strive to secure core technologies for their application. We collaborate with government ministries and local governments to strengthen national competitiveness, discover growth engines for manufacturing, and prepare for the future.

Main Tasks

Cellulose Feedstock Conversion

- Feedstock conversion technology for non-woody biomass and recycled materials

- Ligno-cellulose materialization technology based on TMP (Thermo-Mechanical Pulp)

- Extraction and purification technology for high-purity cellulose raw materials

Nanofibrillation of Cellulose Fibers

- Manufacturing technology of biomass-derived cellulose fibers

- Nanofibrillation technology based on chemical/biological pretreatment processes

- Hydrophobization surface modification technology for cellulose nanofibers

- High-concentration fine nanofibrillation technology

- Biocompatible and edible material technology

Eco-friendly Material Componentization

- CNF composite masterbatch (bioplastics, elastic composites)

- CNF composite emulsions (bio-coating/adhesives, cosmetic formulations)

- CNF-based wet webs (supercapacitors, separators, transformers, air filters)

- CNF-reinforced films (solar module panels, PCBs, food packaging)

- CNF foams (burn/hemostatic dressings, cell culture scaffolds)

Other Fiber Fields

- Antibacterial coating/adsorption technology using agricultural byproducts

- Fibers for bulletproof and stab-resistant applications

- Melt Electrospinning

- Manufacturing technology for medical ceramic resin / teeth whitening agents

- Prototype property analysis and performance evaluation