Research Areas

Korea Textile Machinery Convergence Research Institute

Advanced Materials Research

Core Technologies

Eco-Friendly Material Manufacturing and Componentization Technology

- (Cellulose Raw Materialization) – Conversion of natural and recycled materials into cellulose feedstock.

- (Cellulose Microfibrillation) – Chemical/biological pretreatment, nanofibrillation, and high-concentration microfibrillation.

- (Eco-Friendly Componentization) – Componentization technologies applicable to bio-composites, elastomers, and electronic materials.

phone_in_talk Technical ContactGreen Materials Research Department

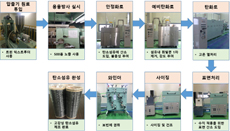

Low-Cost Carbon Fiber Production Technology from Chlorinated PVC

Using CPVC, commonly used for piping in Korea, as a raw material, Enables carbon fiber production without the ‘stabilization’ process, reducing energy use and enhancing cost competitiveness.

phone_in_talk Technical ContactComposite Materials Research Department

Slag Fiber Development and Glass Fiber Replacement Technology

Mass production of mineral long fibers using steel slag and development of composites with them Replaces imported glass fiber and achieves resource circulation and high-value upcycling through industrial waste recycling.

phone_in_talk Technical ContactComposite Materials Research Department

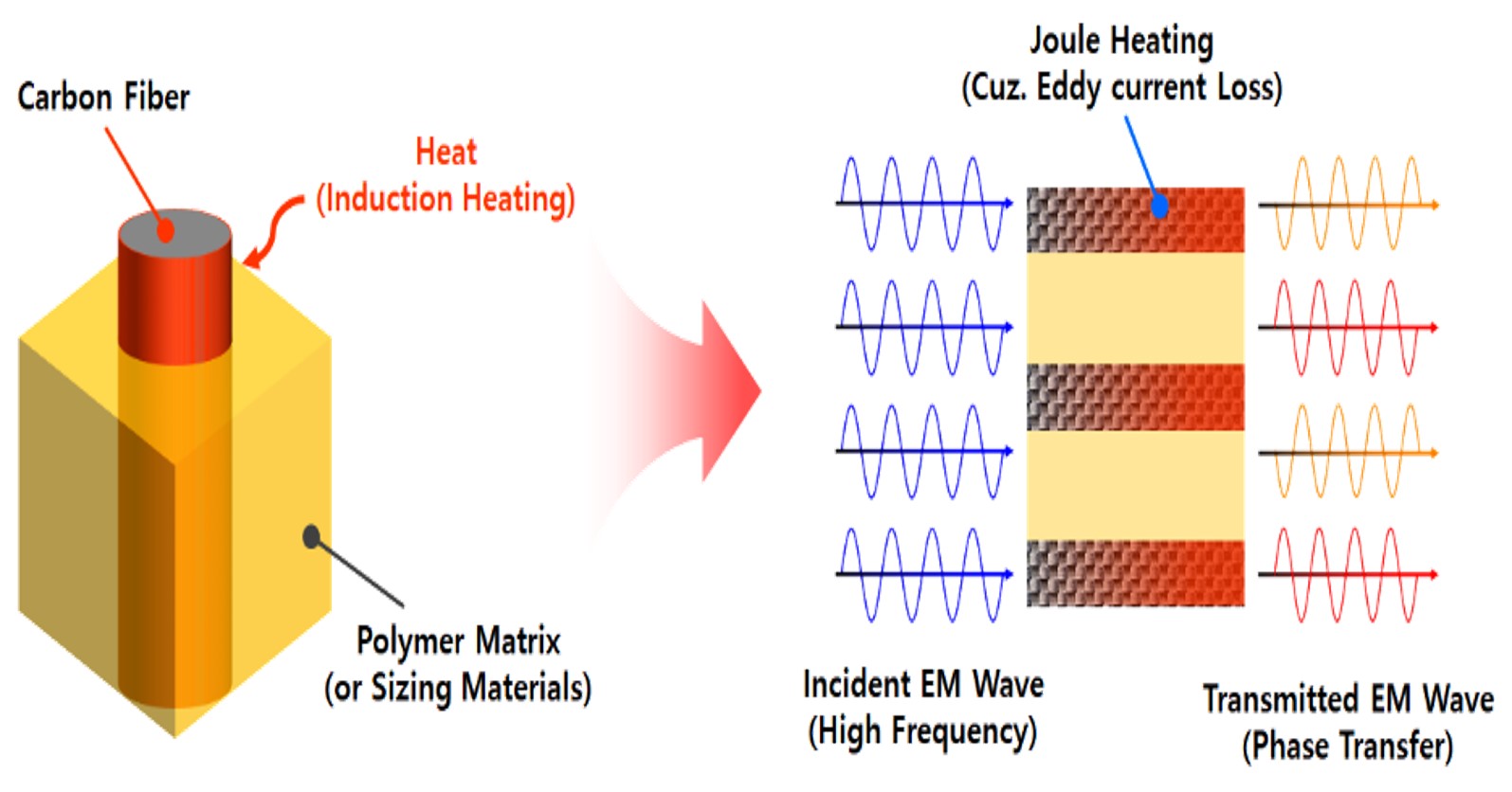

Recycled Carbon Fiber (rCF) Recovery and Re-Utilization Technology from Waste CFRP via Non-Shredding Process

- (rCF Recovery) – Induction heating-based rapid pyrolysis for waste CFRP (discontinuous/continuous rCF)

- (rCF Reuse) – Surface functional group reintroduction (re-sizing) and polymer resin reinfusion technology

- (rCF Componentization) – Manufacturing rCF-based automotive parts, EMI shielding materials, structural and functional components

phone_in_talk Technical ContactComposite Materials Research Department